![]()

|

We now see that our sonofusion replication project has given way to pure research on the phenomenon. Roger's ideas have not worked and we are trying our own ideas to make it work with a more practical device. The sonofusion process is not in question, as we think the helium detection, transmutation, and microvolcanic evidence in the host metals, which were documented by other labs, are legitimate and solid evidence that sonofusion is real. With a close eye on the performance of our ultrasonic wattmeters in our test apparatus, and with greater understanding of our volunteer instrument maker, Chris Eddy of Pioneer Microsystems, we have decided to redesign our ultrasonic oscillator and reactor interface and power monitoring point in the circuit. The wattmeters monitor the instantaneous voltage and current to the sonofusion reactor for real-time, analog, high speed V-I multiplication. The initial ultrasonic wattmeter design accommodated the circuit interface established by Crest, the manufacturer of the oscillator and piezoelectric transducers we are using. Crest mounts inductors in series with the piezo elements as a method of achieving high voltages across the piezos. The series resonance of the inductors and piezos produces a much higher voltage across the piezos than what is applied to this LRC circuit from the oscillator. The inductor-piezo interface is what was readily available to us to connect our wattmeters, as the inductors are mounted on the printed circuit board and external wiring connects the circuit board to the piezos. This created numerous problems, which turned out to be too difficult to overcome.

Chris suggested that we remove the Crest inductors from the Crest oscillator circuit boards and mount them on the reactor. There are several advantages to doing this. Primarily, the voltage and current multiplication will be easier, as the signals will be nearly in phase before the inductors. Secondly, a large voltage divider is no longer necessary to get a proper signal to the integrated circuit inputs; the large voltage divider (1:250) was plagued with reactance problems, as resistors are not pure enough resistances for accurate operation of these meters. Thirdly, dangerous voltages are more isolated on our test bench; 3 kV peaks with 1 amp capability is more than deadly-it can also start fires, and it has. One BNC bulkhead fitting with a plastic insulator caught fire when the insulation broke down and arced. Now the high voltage wiring will be limited to a span of about 5 cm from an inductor to a piezo element. The wiring between the reactor and the oscillator will now be reduced to a mere 350 V peak. Chris has taken back a pair of wattmeters for modification. In the meantime, I have taken the opportunity to examine a potential factor for identifying nuclear fusion. Roger Stringham often produced visible deterioration of his exposed targets. A recent run by me with light water, protium oxide, produced no visible erosion of the exposed titanium surfaces. Could this be an indication that fusion was not occurring? None of our protium oxide runs over the last year produced any significant excess heat, and I did not notice erosion from those tests. Titanium is a hard metal and might not be eroded by ultrasonic energy alone. So I tested my hypothesis by exposing a pair of titanium-faced piezo stacks to protium oxide for 19 days, the same duration as a known pair of transducers which were eroded and exposed to deuterium oxide, heavy water. After 19 days, the light water did erode the titanium. Heat measurements were not made, as the wattmeters were out of commission. All that can be concluded from this test is that there is no difference between heavy water and light water for its visual effects on titanium. If there were a difference, we would investigate further. Our difficult and inconclusive observations of excess heat could benefit from another indicator of cold fusion occurring. We will keep looking. The titanium erosion may be due to the formation of titanium hydride, a stable and insoluble compound. We have purchased a highly stable signal generator, a Hewlett-Packard HP-33120A, and a spectrum analyzer, a Link Instruments DSO-2102M. These instruments will allow us to match impedance curves of each piezo transducer just in case this is important for proper system operation. It could be that Roger Stringham found consistently positive results because he had fortuitously matched transducers. He used the same ones for years, and this could be the reason for his observed high repeatability. A Modified Reich-Einstein Experiment

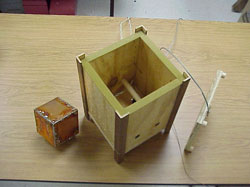

Our laboratory has produced notably small temperature differentials in the Reich-Einstein experiment. This may be because of the metal roofing of our building acting as a shield, as a partial Faraday cage. See IE Nos. 37 and 41 to compare our temperature differentials with those measured by the Correas. The effect manifested not as strongly here-and under the particular conditions of our testing. Knowing this handicap, we have begun experiments aimed at measuring a heat flow from the copper cube with the wooden SEC. Without resorting to statistical evaluation of the datalogger data file, we saw no heat released over nearly a week, while weather patterns changed. The visible noise floor for the graphically presented data is less than 50 mW. We do not know how much shielding the thermocouple coverage around the SEC is producing, as metal screen is often used effectively for Faraday cages. We may be inadvertently diminishing the effect by the presence of the totally surrounding thermocouple wires. The test apparatus will be moved off-site to a location where there is a stable thermal environment and little metal to alter the aether energy fluxes which Reich, the Correas, and others have measured. We will report the results of this in a future issue.

|

||||